How Sensitive Washi Tape Suppliers Ensure Quality in Every Roll

Release Time:

2025-06-10

Source:

How Sensitive Washi Tape Suppliers Ensure Quality in Every Roll

Table of Contents

- Introduction to Sensitive Washi Tape

- The Importance of Quality in Washi Tape

- Sourcing High-Quality Materials

- Advanced Manufacturing Processes

- Quality Control Measures: Ensuring Consistency

- Packaging and Distribution: Protecting Quality

- Sustainable Practices in Washi Tape Production

- Choosing the Right Sensitive Washi Tape Supplier

- Conclusion: Commitment to Quality in Every Roll

- FAQs About Sensitive Washi Tape

Introduction to Sensitive Washi Tape

Sensitive washi tape has become a popular choice among artists, crafters, and businesses alike. With its unique aesthetic appeal and versatility, this adhesive tape offers a plethora of creative options. However, not all washi tape is created equal. The quality of the tape can significantly affect its usability and the overall outcome of projects. Thus, understanding how sensitive washi tape suppliers ensure quality is essential for anyone looking to purchase this product.

The Importance of Quality in Washi Tape

Quality in washi tape is vital for several reasons:

Durability and Adhesion

High-quality washi tape adheres well to various surfaces, allowing for easy application and removal without leaving sticky residue. This quality is crucial, especially for projects that require precision.

Visual Appeal

The aesthetic properties of washi tape, including color vibrancy and pattern clarity, depend largely on the quality of materials used. Premium suppliers ensure that their products meet high visual standards.

Versatility in Application

Quality washi tape can be used for different purposes, from decorating journals to packaging products. Suppliers who prioritize quality cater to a wide range of applications.

Sourcing High-Quality Materials

The foundation of superior washi tape lies in the materials used during production. Trusted sensitive washi tape suppliers prioritize sourcing the best raw materials, including:

Natural Fibers

Many washi tapes are made from natural materials such as rice paper, which provides a unique texture and strength. Suppliers carefully select high-grade fibers to enhance the tape's quality.

Adhesives

The type of adhesive used is critical. High-quality, non-toxic adhesives ensure that the tape sticks well while being safe for various applications.

Ink Quality

The inks used for printing designs on washi tape must be of high quality to avoid fading or bleeding. Suppliers invest in superior inks that are vibrant and long-lasting.

Advanced Manufacturing Processes

The production process of washi tape involves various stages that contribute to the final product's quality. Leading suppliers employ advanced manufacturing techniques, which include:

Precision Cutting Techniques

Accurate cutting machinery ensures that every roll has uniform width and length. This precision is essential for both aesthetic appeal and practical use.

Consistent Printing Methods

Advanced printing technology allows for intricate designs and patterns to be transferred onto washi tape with clarity. Quality suppliers utilize state-of-the-art equipment to maintain consistency across batches.

Controlled Environment Production

Maintaining a controlled environment during production helps in preventing contaminants and ensuring that the materials remain in optimal condition throughout the manufacturing process.

Quality Control Measures: Ensuring Consistency

Quality control is a cornerstone of any reputable washi tape supplier. Comprehensive quality checks at various stages of production ensure that each roll meets established standards.

Raw Material Inspection

Before production begins, suppliers conduct thorough inspections of raw materials to ensure they meet quality specifications.

In-Process Testing

Throughout the production process, samples are tested for adhesion strength, colorfastness, and overall durability to catch any potential issues early.

Final Product Evaluation

Once rolls are completed, they undergo a final quality assessment. This step includes checking for defects, ensuring proper labeling, and confirming that packaging is intact.

Packaging and Distribution: Protecting Quality

Quality doesn’t just end at production; how sensitive washi tape is packaged and distributed plays a significant role in maintaining its integrity.

Protective Packaging Materials

Suppliers use high-quality packaging materials that protect the tape during transit and storage. Proper packaging prevents damage and preserves the tape's quality until it reaches the customer.

Efficient Distribution Channels

Reliable distribution methods ensure that products reach their destinations in optimal condition. Suppliers often work with trusted logistics partners to maintain quality throughout the supply chain.

Sustainable Practices in Washi Tape Production

Increasingly, consumers are looking for products that are environmentally friendly. Sensitive washi tape suppliers are adapting by adopting sustainable practices, such as:

Eco-Friendly Materials

Using biodegradable materials and sustainable sourcing practices helps reduce the environmental impact of washi tape production.

Waste Reduction Initiatives

Implementing processes that minimize waste during manufacturing contributes to more sustainable production. Top suppliers aim for zero waste by recycling scrap materials.

Community Engagement

Engaging with local communities and supporting sustainable initiatives enhances not only brand reputation but also contributes to a healthier ecosystem.

Choosing the Right Sensitive Washi Tape Supplier

When selecting a sensitive washi tape supplier, consider the following factors to ensure quality:

Reputation and Reviews

Research potential suppliers by examining customer reviews and industry reputation. A supplier with positive feedback is more likely to provide high-quality products.

Certifications and Standards

Verify if the supplier adheres to industry standards and holds relevant certifications, indicating commitment to quality.

Customer Support and Communication

Choose a supplier that offers excellent customer support. Clear communication regarding product specifications, shipping, and returns can enhance your purchasing experience.

Conclusion: Commitment to Quality in Every Roll

Understanding how sensitive washi tape suppliers ensure quality in every roll is essential for making informed purchasing decisions. From sourcing high-quality materials to employing advanced manufacturing processes and rigorous quality control measures, every aspect of production matters. By choosing reputable suppliers who prioritize these elements, consumers can ensure they receive washi tape that not only meets but exceeds their expectations.

FAQs About Sensitive Washi Tape

1. What is washi tape made of?

Washi tape is typically made from natural fibers, including rice paper, which gives it its unique texture and strength.

2. How do I know if the washi tape is of good quality?

Look for suppliers that provide detailed information about their materials, production processes, and quality control measures. Reviews from other customers can also offer insights.

3. Can washi tape be removed without leaving a residue?

High-quality washi tape is designed to be removable and should not leave a residue on surfaces when properly applied.

4. Are there eco-friendly options for washi tape?

Yes, many suppliers are now offering eco-friendly washi tape made from biodegradable materials and sustainable practices.

5. What applications are best suited for washi tape?

Washi tape is versatile and can be used for crafting, decorating, gift-wrapping, labeling, and more. Its ability to adhere well to various surfaces makes it a favorite among artists and crafters.

Related Information

How Sensitive Washi Tape Suppliers Ensure Quality in Every Roll

How Sensitive Washi Tape Suppliers Ensure Quality in Every Roll Table of Contents Introduction to Sensitive Washi Tape The Importance of Quality in Washi Tape Sourcing High-Quality Materials Advanced Manufacturing Processes Quality Control Measures: Ensuring Consistency Packaging and Distribution: Protecting Quality Sustainable Practices in Washi Tape Production Ch

Exploring the Global Landscape of Smooth Surface PE Tape Exporters

Smooth surface PE tape has gained significant popularity in various sectors, including packaging, crafts, and industrial applications, due to its versatility and durability. As a professional in the light industrial daily necessities sector, particularly focusing on labels, adhesive tapes, and self-adhesive products, knowing about smooth surface PE tape exporters can provide you with a strategic a

Why EVO Colored Masking Tape is Essential for Artists and Creatives

Why EVO Colored Masking Tape is Essential for Artists and Creatives Table of Contents 1. Introduction to EVO Colored Masking Tape 2. What is EVO Colored Masking Tape? 3. Unique Properties of EVO Colored Masking Tape 4. Advantages of Using EVO Colored Masking Tape for Artists 5. Creative Applications of EVO Colored Masking Tape 6. Tips for Using EVO Colored Masking Tape

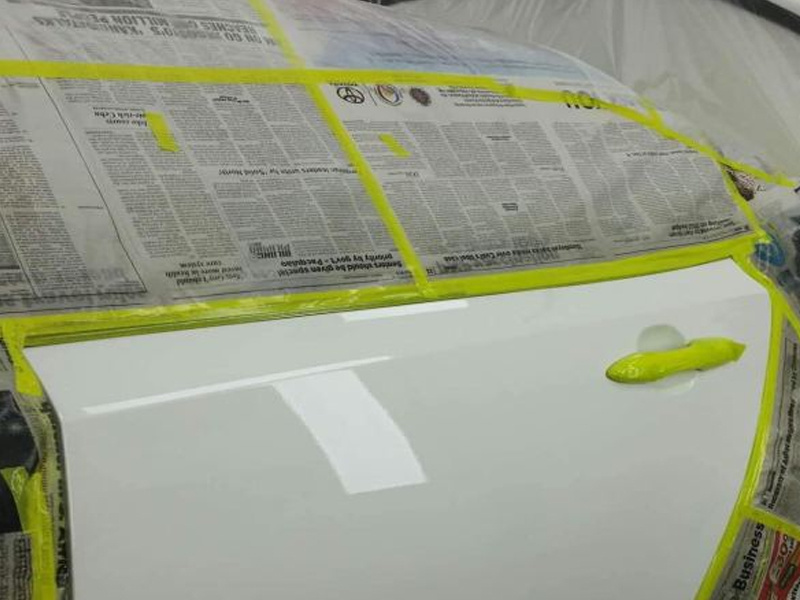

Exploring the Benefits and Applications of Automotive Refinish Washi Tape in China

Automotive refinishing is a critical process in the vehicle maintenance and repair industry, and the use of specialized materials significantly enhances the quality of the final finish. One such material is automotive refinish washi tape, which has become increasingly popular in China due to its unique properties and advantages. This tape is not merely a simple adhesive product; it is designed to